Air System Troubleshooting

Tank system leaks

The HP50 tanks and integrated regulator bottle valves are assembled with all o-ring fittings. This means that they can be loosened or lose tension over time. If anything is leaking on the regulator valve (gauge, scuba whip, fill port, overpressure burst valve, bottle valve) try lightly tightening the fitting with an appropriate wrench. If still leaking, regulator will have to be rebuilt by a certified service shop.

Manifold or check valve leak.

The quick disconnect valve nipples on the manifold assembly are tightly installed on the manifold with an NPT fitting, and are sealed permanently. It is unlikely that they are leaking from here.

The bleed sleeves are sealed with two o-rings, and can be unscrewed and inspected. Using an o-ring removal tool (plastic hook/probe) pull the o-ring’s out of their lands and inspect them for cracks or splits. If any damage is visible, replace the o-ring with one from the repair kit and reinstall. Re-test for leak and proceed. If bleed sleeve is still leaking, replace the sleeve.

The check valve, inside the quick disconnect fitting is also an o-ring fitting. If the fitting is leaking out of one of these, the easiest solution is to add another bottle and continue mission, noting the leak for maintenance. These are however, not easily user serviceable.

Main Air Line leak

The manifold is connected to the STT-Inflation Valve Assembly with a braided supply line with a -6 A/N fitting at both ends. These fittings are unlikely to come loose, but if maintained improperly, they can appear connected while still developing a leak. Simply put a wrench on the fitting and tighten lightly. You do not need to overtighten. With only a few pounds of pressure, the A/N fittings are rated for thousands of PSI in the line.

Inflation Valve Assembly Leak

Refer to the first section in this chapter for troubleshooting the STT-IVA system.

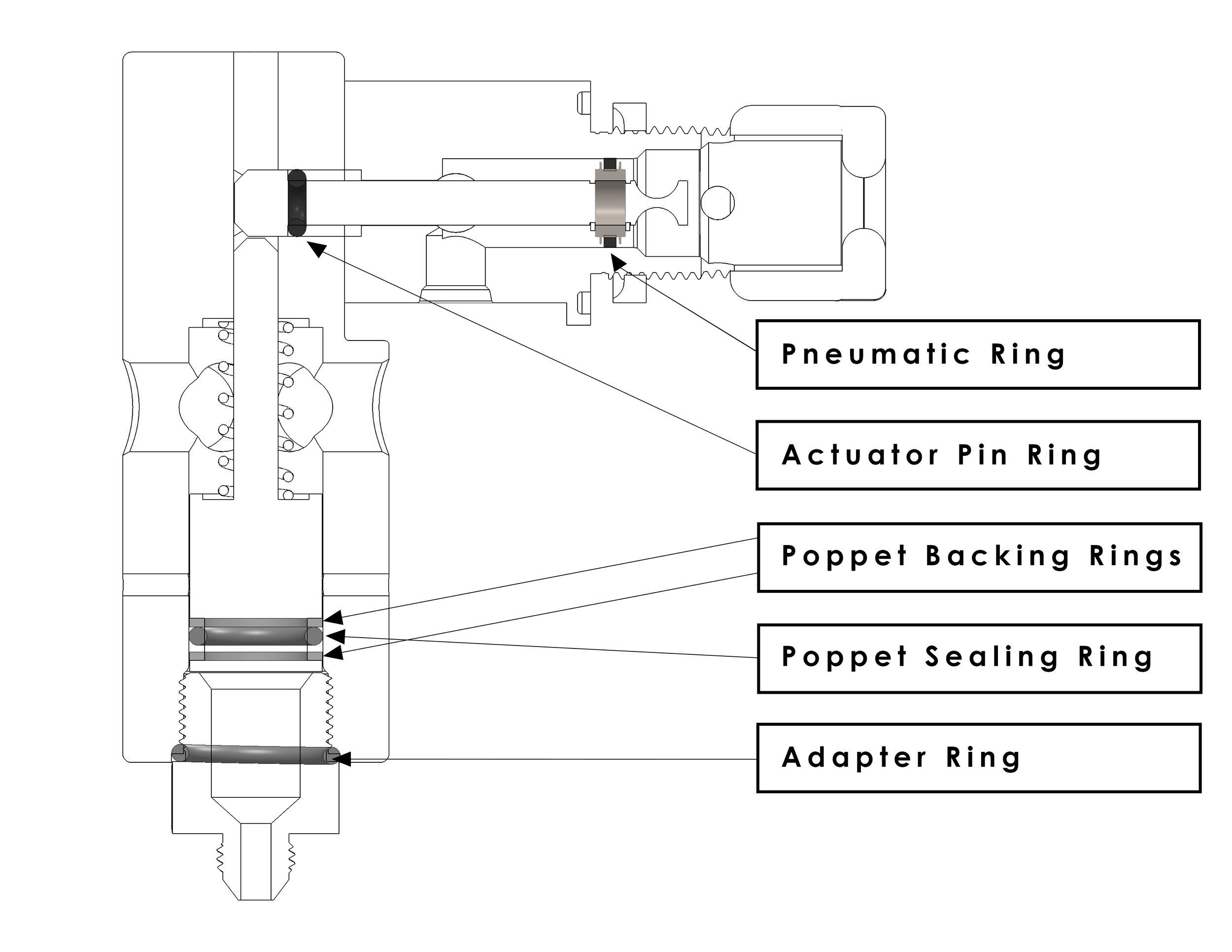

O-Ring Diagram