Inflation Valve Troubleshooting

Leaking IVA Body

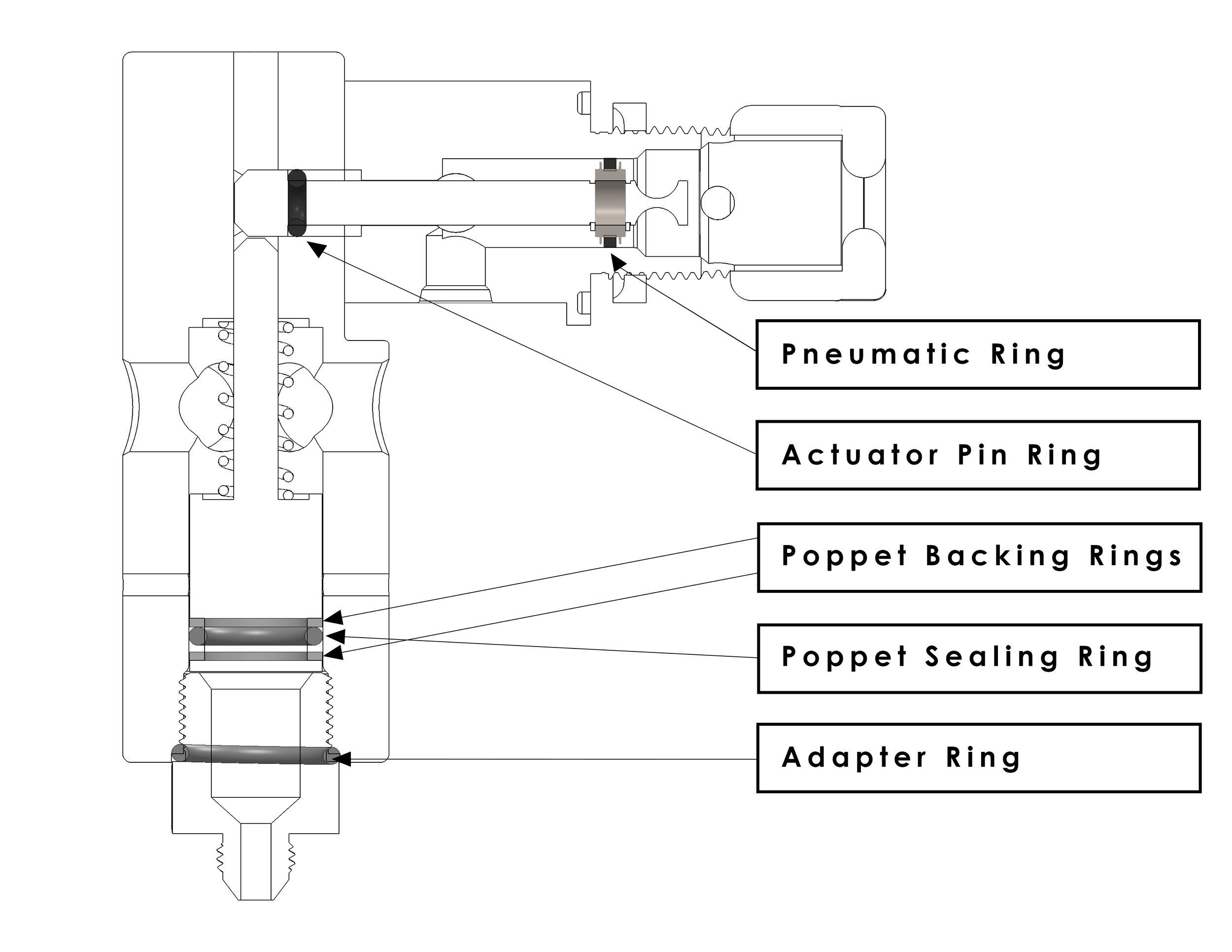

The Inflation Valve Assembly is sealed completely with O-rings, among the most reliable pneumatic sealing methods available. This means that there is zero sealant or flat gaskets to deteriorate or fail.

O-rings do however require eventual maintenance over a time horizon of years though, and it is possible that the rings could degrade to where one would leak if not regularly maintained as per the recommended annual schedule.

A full complement of o-rings is provided in the “STT-IVA Rebuild Kit” along with instructions to rebuild in the field if necessary.

Check both A/N fittings between the manifold and IVA to ensure they are tight.

If it isn’t the connectors, the only two o-rings under system pressure are those on the poppet and the AN Adapter. Both are easily accessed and replaced. To determine which is leaking, if not obvious, prepare a solution of dish soap and water to spray onto the IVA itself. The leak detection solution will bubble quickly in the presence of a leak.

If it’s leaking from the bottom of the valve, it’s the adapter O-ring.

If it’s leaking from the maintenance window area, it is the Poppet Sealing ring.

O-Ring Diagram

Inflation Valve Troubleshooting

Can’t put the actuator safety pin through body when resetting.

The actuator safety pin is only able to be installed when the actuator pin is all the way in battery. If the pin isn’t all the way “back” it will prevent the pin from passing through.

Try actuating the pin carefully forward and backward with a pair of needle nose pliers reached into the actuator from the front. If it simply won’t push in, it is possible that the poppet hasn’t reset all the way in the valve bore, and it needs to be reset manually. This has never happened, but it’s the only possible reason.

With the actuator pin pulled as far “out” as possible, use a thin tool like a 3/16” Allen wrench or small screwdriver (shown on diagram in red) to push the poppet back in place by pushing down through the poppet bore hole on the top of the valve. This bore hole is accessed through an empty hole on the centerline of the back plate, 1/2” above the bottom stainless screw.

Check both A/N fittings between the manifold and IVA to ensure they are tight.

If it isn’t the connectors, the only two o-rings under system pressure are those on the poppet and the AN Adapter. Both are easily accessed and replaced. To determine which is leaking, if not obvious, prepare a solution of dish soap and water to spray onto the IVA itself. The leak detection solution will bubble quickly in the presence of a leak.

If it’s leaking from the bottom of the valve, it’s the adapter O-ring.

If it’s leaking from the maintenance window area, it is the Poppet Sealing ring.

O-Ring Diagram